Researchers from SUT increase capacity to develop frozen food packaging.

Researchers from SUT increase capacity to develop frozen food packaging SUT researchers break the limitations of bioplastics ready to develop “Frozen food packaging that is environmentally friendly” with high heat resistance Sterilization standard level On March 22, 2023, at the Information Room, SUT Administrative Building, Professor Dr. Nueng Tia-amrung, Vice President for Technology Research and Development, SUT said, “As a specialized university in science and technology. technology with the goal of driving the university through research and development of innovations that meet social needs Make an impact on the development of the quality of life, economy and society at the national level. coupled with the creation of new academic knowledge to be accepted both nationally and internationally Announcement of research and innovation results “Environmentally friendly packaging for canned food and frozen food. biodegradable"

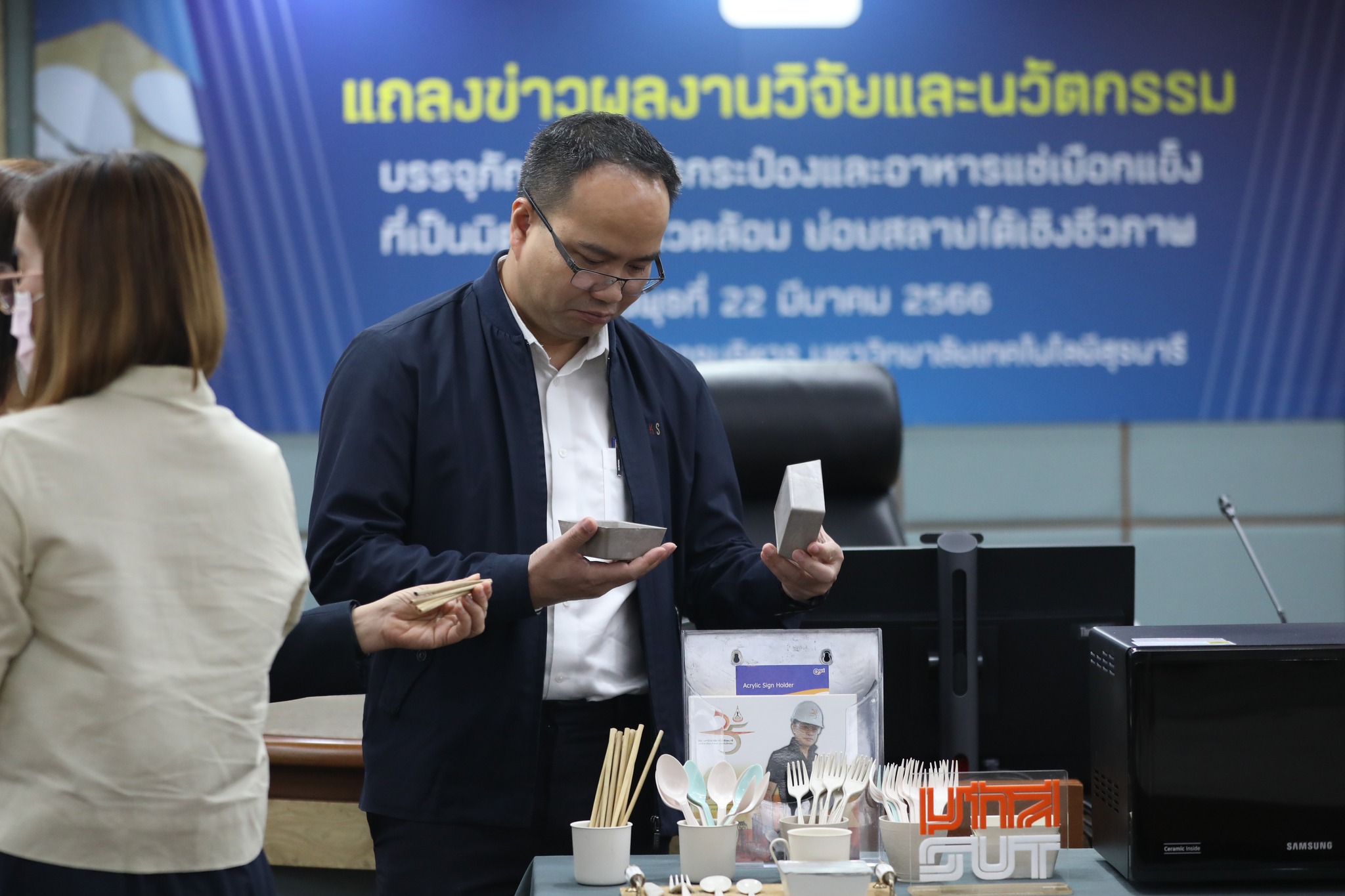

by Assistant Professor Dr. Uthai Meekham, Lecturer in Design Technology The School of Engineering SUT has brought knowledge Expertise in polymer engineering combined with product design skills Resulting in bioplastic packaging with special properties suitable for the production process of frozen food packaging and canned food packaging. that can be adapted to the Thai food industry, increasing market value Supports a wider range of applications It is another innovation that is ready to transfer technology to interested entrepreneurs immediately. Respond to the new economic development model towards sustainable development. By driving the economy in 3 areas simultaneously: Bio Economy, using biological resources to create added value, linking with the Circular Economy, taking into account the use of various materials. come back to take full advantage coupled with the use of environmentally friendly production technology Also known as the Green Economy (Green Economy) in a balanced way.

stable and sustainable Assistant Professor Dr. Uthai Meekham, a researcher whose work reveals that “Nowadays, consumers pay more attention to health and environmental safety. This can be seen from the packaging made from bio-based materials. (Bio-Degradable Packaging) and degradable within 2 - 5 months according to landfill process standards. Has received more and more attention to be used as a food container To replace the use of general plastics produced from petrochemicals, it takes more than 400 years to decompose, creating the problem of residual waste. and toxic to the environment. research and development innovation innovation “Environmentally friendly packaging for canned food and frozen food. Biodegradable" has studied research to break the general limitation. And increase the ability of bioplastics (Bioplastic) from normal heat resistance at 50 degrees Celsius, developing properties to heat resistance up to 150 degrees Celsius and from laboratory tests.

Can be further developed for industrial purposes in terms of packaging for canned food according to the important canned food production process standards that must be sterilized at a temperature of 121 degrees Celsius with a pressure of 15 psi (PSI) for a period of time 15 minutes From this success, it will open the way for further development for Thailand's food export industry that aims to expand the base of consumers who are health conscious and environmentally friendly. It also increases the diversity of the use of bioplastics. There are no requirements for packaging styles that are qualified to support the frozen food industry very well. As for the commercial viability from the study in terms of cost and production control Able to control costs to not be very high or close to general plastic with the main factor being Bio-based materials from natural PLA plastics are regularly supplied by manufacturers to the market. and injection molded inputs that can be used to produce the original bioplastic packaging as usual This can reduce the cost of this part a lot.

The cost is about 50 satang – 1 baht per pack, which is considered to increase the product value of the food industry. Now the world is focusing on products that are conservative and environmentally friendly. Importantly, it is highly safe for consumers. Therefore, it is another factor that helps drive market value. Some European countries have seriously enacted laws to promote the use of bio-environmentally friendly packaging. Along with the fact that Thailand has been announced as the world's kitchen, it is outstanding in the food industry. The development of packaging for canned food and frozen food that is environmentally friendly and biodegradable is one of the world's top countries in the world. consumers and care about the environment This is in line with the global demand for Sustainable Development Goals-SDGs that cover social, economic and especially environmental dimensions. Interested persons can contact Asst. Prof. Dr. Uthai Mee Kham Kham, Department of Design Technology. School of Engineering Suranaree University of Technology

https://www.facebook.com/media/set/?set=a.663277095605133&type=3

References: